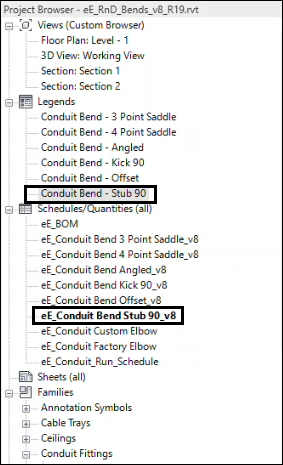

Stub 90

eVolve Electrical contains and utilizes the most powerful, feature packed bend families in the industry. These families have been developed with the user in mind and allow for total customization. Becoming familiar with commonly used parts and their functions can open up a world of options that cant be found elsewhere.

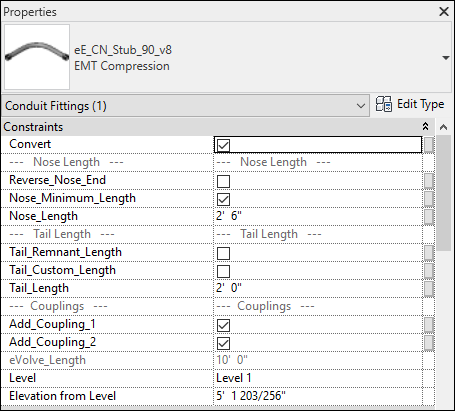

Instance Properties

Convert- Check to activate and manipulate the bend family.

Reverse Nose End- Switches which end is the nose end of the bend.

Nose Minimum Length-Nose is created to the minimum size allowed by project bend settings. This is the default setting.

Nose Length- Manually set the minimum nose length. Uncheck Nose Minimum Length and enter length. (Greater than minimum length and less than max conduit length)

Tail Remnant Length- Check to utilize the balance of the remaining conduit in that tail segment.

Tail Custom Length- Check to activate the Tail Length parameter below.

Tail Length- Manually set the tail length. (Must be within the 10' max segment minus the bend length)

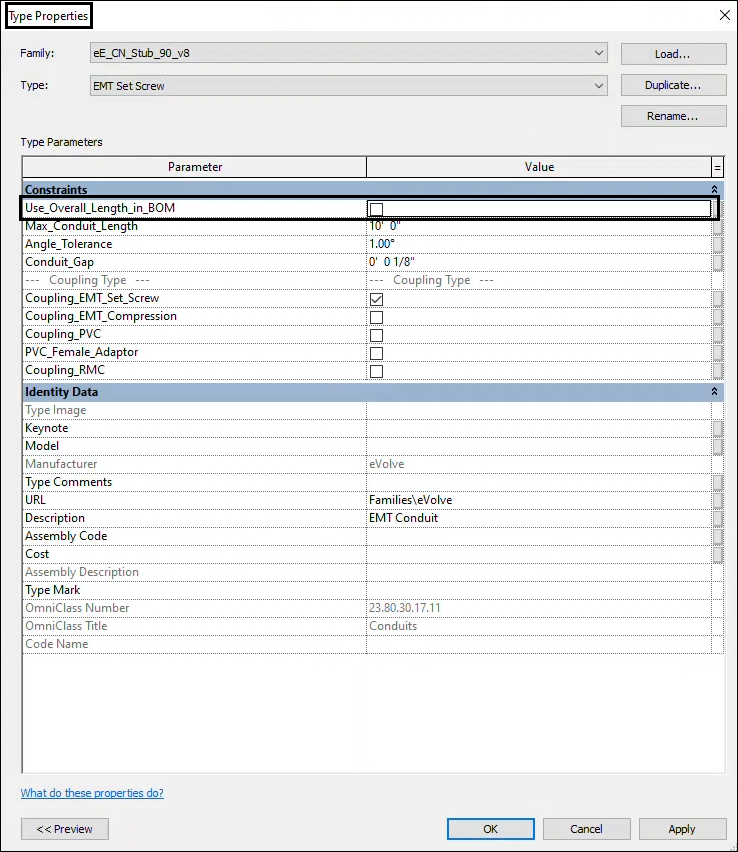

Type Properties

Use Overall Length in BOM- eVolve length gets reported but can use overall length instead of max conduit length for just length of bend

Max Conduit Length- Limits the length of the bend to a stick or less.

Angle Tolerance-Tolerance range for factory elbows. Sets the tolerance allowed for drawn bend angles that aren't quite standard angles. (ex, drawing a 43 degree bend rather than 45 degree)

Conduit Gap-The gap between the coupling & conduit end

Description- Determines the material name added to the eVolve description name.

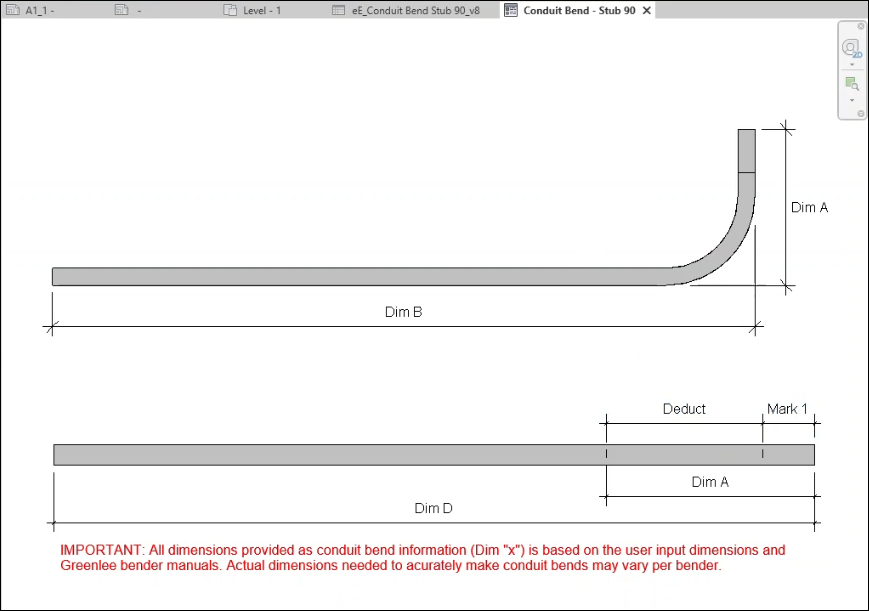

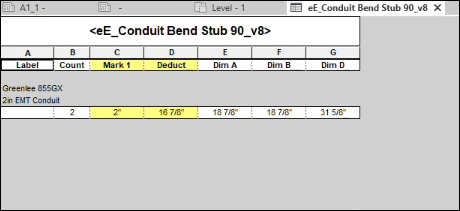

BOM & Legend

In the eVolve Template, each bend family has its own legend and BOM for fast and easy access to information.